Re: ChrisHager's 79 J-10 Build Thread

Posted: Mon Jun 02, 2014 12:24 pm

Excellent! I can't wait to try it out!

Thanks for the tips. The following post addresses the proportioning valve...Nutz-n-Bolts wrote:Bleeding brakes can be a pain.

I "bench bled" my MC while it was installed in the jeep. My assembly was taken off drained and painted up, but I never took the MC off the booster. So fast forward everything is hooked up but no fluid in the reservoir. I just connected a fitting to each port with a connected tube going right back up in to the reservoir. I used rubber hose clamped over the fittings, but you could use chopped off chunks of brake lie too. Just pump until the bubble go away.

Next put lots of towels below to catch drips. As fast as you can unscrew one bleed tube and connect your regular hard line. Repeat for the second line.

Now it's just normal bleeding starting from the farthest wheel back two first, front passenger next and last front driver. I used one of those vacuum bleeders and they are worth every cent!

I have seen that you may need to hold a pin at the proportioning valve so that it allows you to bleed the lines but I did not using my method and it bled fine.

Hope this helps!

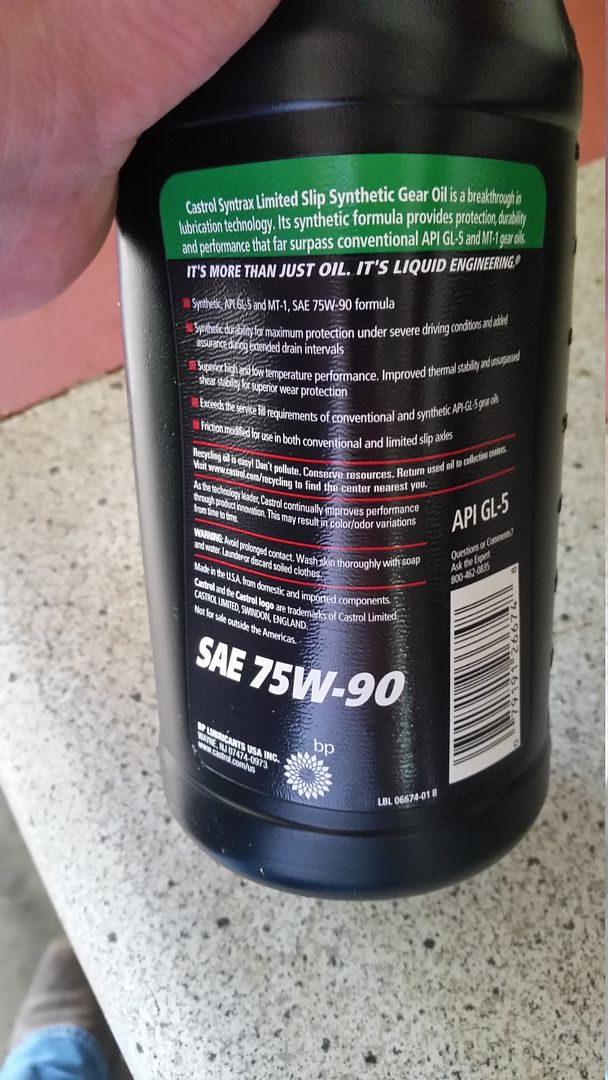

Amazon sells it for about $16/quart with prime shipping: http://www.amazon.com/Red-Line-50304-Tr ... s=red+linehttp://www.redlineoil.com/product.aspx?pid=46&pcid=7 wrote:

Red Line MT-90 75W90 GL-4 Gear Oil

- 75W90 GL-4 gear oil (similar to SAE 5W40/10W40 engine oil viscosity)

- Popular in Nissan, Mazda, Mitsubishi, VW/Audi, Lotus Elise/Exige, Toyota

- Offers quicker shifts, perfect synchronizer coefficient of friction

- Safe for brass synchros, as it lacks the reactive sulfurs found in most GL-5 oils that cause damage

- High performance gear protection and longer synchro life

- Eliminates notchy shifting, even when cold

- Satisfies the gear oil viscosity requirements of 75W, 80W and motor oil viscosities of SAE 40, 10W40, and 15W40

- Recommended for GL-1, GL-3, and GL-4 applications, as well as where most special synchromesh fluids are specified

- Appropriate coefficient of friction for most manual transmission synchronizers (other's synthetic gear oils are often too slippery for proper synchro engagement)

- Red Line offers lubricants to pinpoint nearly every transmission application

- MTL, MT-85 & MT-90 are not for use in differentials with hypoid gears

- Excellent gear and synchro protection, balanced slipperiness for easier shifting in cold climates

- Excellent for high- and low-mile transmissions

- Compatible with petroleums and other synthetics