83 Cherokee resto-mod

-

SOLSAKS

- Posts: 65

- Joined: Wed Mar 22, 2017 6:44 am

Re: 83 Cherokee resto-mod

just seeing this build for the first time today,.....really impressive, first class work all the way.

one of the best I have ever seen,....do the neighbors know what miracles have taken place in your garage ?

going to be one of the nicest FSJ's on the planet.

dave in NC

one of the best I have ever seen,....do the neighbors know what miracles have taken place in your garage ?

going to be one of the nicest FSJ's on the planet.

dave in NC

-

Laredo Matt

Topic author - Posts: 336

- Joined: Fri Jan 08, 2021 3:32 pm

- Location: Washington

Re: 83 Cherokee resto-mod

Thanks Dave. I appreciate your comment.

I've learned a lot and gotten great ideas from other incredible builds and work shared here on the site. It's been a lot of work, mostly fun, and I'm getting to build the jeep just how i want it so that is hard to beat

I've learned a lot and gotten great ideas from other incredible builds and work shared here on the site. It's been a lot of work, mostly fun, and I'm getting to build the jeep just how i want it so that is hard to beat

Matt

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

-

wimsurf

- Posts: 191

- Joined: Sat Sep 17, 2016 1:22 pm

- Location: Holland

- Contact:

Re: 83 Cherokee resto-mod

Hey Matt, how is your build going?

Love the level of detail you added with your roof. And totally understand your choice for a manual transfer, I really wanted to go auto as well but could not find a single unit that worked separately from the ecu.

Drama!

Verzonden vanaf mijn iPhone met Tapatalk

Love the level of detail you added with your roof. And totally understand your choice for a manual transfer, I really wanted to go auto as well but could not find a single unit that worked separately from the ecu.

Drama!

Verzonden vanaf mijn iPhone met Tapatalk

1984 grand wagoneer

https://www.fsjnetwork.com/forum/viewto ... 35#p197535

- topaz gold | deep night blue,

- AMC 360 v8 | 2019 5.7 hemi,

- TF727 auto 3 speed | 8hp70 8 speed

- nutmeg interior | sand or almond interior to be decided

https://www.fsjnetwork.com/forum/viewto ... 35#p197535

-

Laredo Matt

Topic author - Posts: 336

- Joined: Fri Jan 08, 2021 3:32 pm

- Location: Washington

Re: 83 Cherokee resto-mod

Thanks for checking in. I haven't been on the site for a couple of weeks. I had a few things come up that pulled me away from the jeep. The build has been going but slower than would like. I plan to post an update soon, if not this weekend.

wimsurf wrote: ↑Tue Jul 19, 2022 10:29 am Hey Matt, how is your build going?

Love the level of detail you added with your roof. And totally understand your choice for a manual transfer, I really wanted to go auto as well but could not find a single unit that worked separately from the ecu.

Drama!

Verzonden vanaf mijn iPhone met Tapatalk

Matt

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

-

Laredo Matt

Topic author - Posts: 336

- Joined: Fri Jan 08, 2021 3:32 pm

- Location: Washington

Re: 83 Cherokee resto-mod

It's been a few months since I updated the thread so will do a all-in-one catch up post

I've continued plugging along, just a bit slower as life has gotten in the way.

Below are a few the things I got knocked out.

- transfer case installed ...tight but made it.

- new engine harness

- printed mount to support ECM, front InfinityBox power cell and ECM fuse block

- weatherstip installed on on inner fenders, front core support

- A/C evaporator mount in place

- Modified defrost ducts to fit

- Modified battery tray to fit Optima DH6

- Dash painted (I had a shop do it, just no time and took my temp paint booth down)

- finished interior dynamat

- front door weather stripping, power mirrors, power window assemblies and glass, pulls and locks installed

- purchased fuel pump and gas tank ready for install now

- ordered parts, parts and more parts

Ended up doing a lot more than listed now that I've looked back at pictures but this is current status. One day soon it will all come together and start looking different. I keep telling myself that

T-Case installed. Still have to make the linkage but that was a hurdle

New harness that has support for the PWM fuel pump, correct FPCM, heat wrapped and done right.

Have a buddy who is a design engineer so sent him the parts, told him what I wanted and he designed and printed an mount.

ECM / fuse mount

InfinityBox power cell mounted

Couldn't find a body shop with staple gun and looked at the plastic fender inserts but decided to just drill and rivet the body panel weatherstrip.

AC evaporator mount to firewall installed. Fabricated a mount for the front side plate as well and welded in (you can see at top of second picture) ...and it is all level in all directions to my surprise

Was tight under dash with factory defrost ducts so modified VA universal ducts to fit. Gave me about 4" more inches of clearance which is exactly what I wanted

Compared to factory

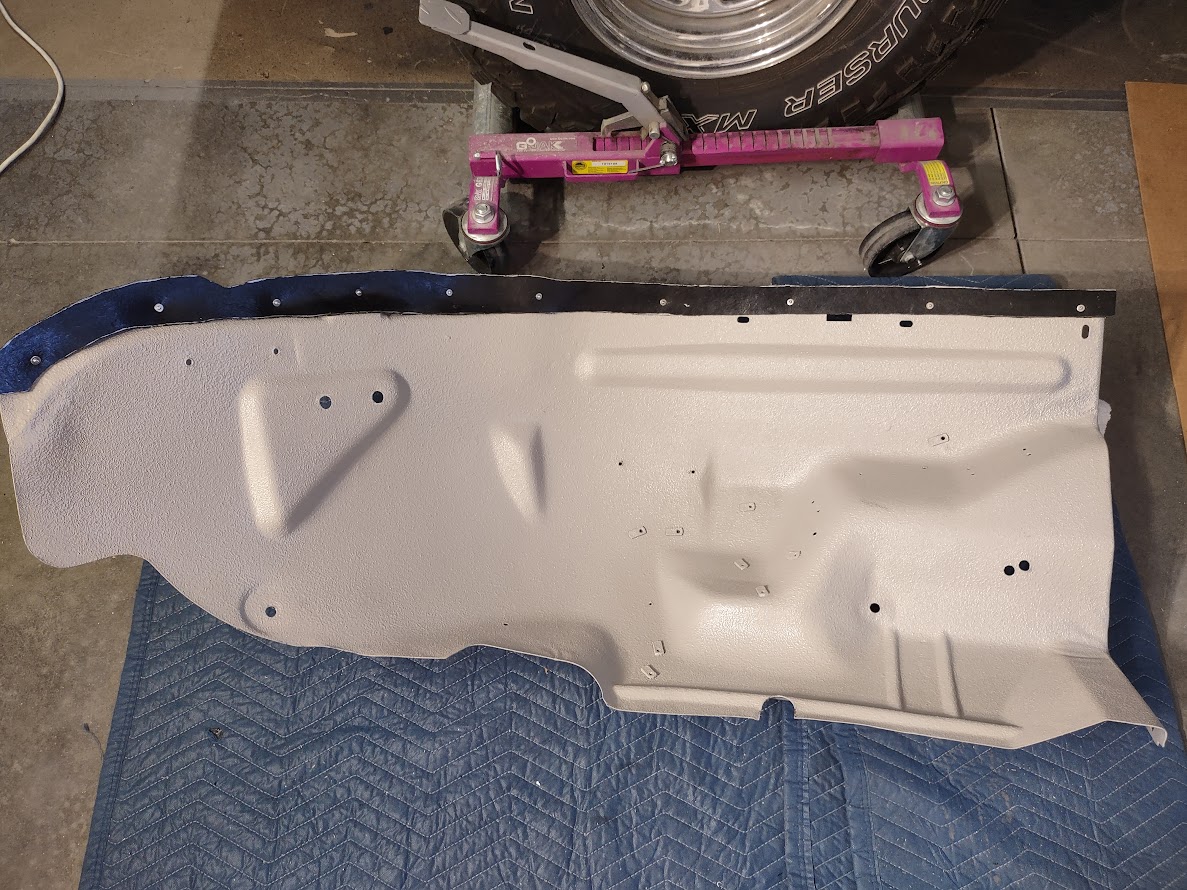

Shaved down, rivet holes drilled and tested and ready for epoxy

ready to go... seam sealer applied after epoxy fully cured

a nice tight fit to dash with plenty of working room

Added 1/2" width the battery tray to accommodate the Optima DH6. Small effort for meaningful increase in battery performance.

finished welding, grinding and then smoothed it out with a light body work before paint

Dash has been in and out so many times now for test fits, checking clearances etc. it is getting hard to count.

Another test fit after finishing up doors, mirrors etc to test for AC evaporator and measure for steering shaft length. Currently out again to add a third dash vent on the driver side. To fill the big spot I thought was going to be used for an electronic transfer case switch

Went with a ZL1 PWM pump module. Plugs right into my harness without modifications and the ECM will manage it as GM intended. Plus, should have spares long into the future if needed.

Have a BJs tank so had the pre-cut mounting holes welded up and new mounting locations cut. Probably spent at least two hours risning/repeating and then cleaning with wet back to get rid of all the shavings.

I've continued plugging along, just a bit slower as life has gotten in the way.

Below are a few the things I got knocked out.

- transfer case installed ...tight but made it.

- new engine harness

- printed mount to support ECM, front InfinityBox power cell and ECM fuse block

- weatherstip installed on on inner fenders, front core support

- A/C evaporator mount in place

- Modified defrost ducts to fit

- Modified battery tray to fit Optima DH6

- Dash painted (I had a shop do it, just no time and took my temp paint booth down)

- finished interior dynamat

- front door weather stripping, power mirrors, power window assemblies and glass, pulls and locks installed

- purchased fuel pump and gas tank ready for install now

- ordered parts, parts and more parts

Ended up doing a lot more than listed now that I've looked back at pictures but this is current status. One day soon it will all come together and start looking different. I keep telling myself that

T-Case installed. Still have to make the linkage but that was a hurdle

New harness that has support for the PWM fuel pump, correct FPCM, heat wrapped and done right.

Have a buddy who is a design engineer so sent him the parts, told him what I wanted and he designed and printed an mount.

ECM / fuse mount

InfinityBox power cell mounted

Couldn't find a body shop with staple gun and looked at the plastic fender inserts but decided to just drill and rivet the body panel weatherstrip.

AC evaporator mount to firewall installed. Fabricated a mount for the front side plate as well and welded in (you can see at top of second picture) ...and it is all level in all directions to my surprise

Was tight under dash with factory defrost ducts so modified VA universal ducts to fit. Gave me about 4" more inches of clearance which is exactly what I wanted

Compared to factory

Shaved down, rivet holes drilled and tested and ready for epoxy

ready to go... seam sealer applied after epoxy fully cured

a nice tight fit to dash with plenty of working room

Added 1/2" width the battery tray to accommodate the Optima DH6. Small effort for meaningful increase in battery performance.

finished welding, grinding and then smoothed it out with a light body work before paint

Dash has been in and out so many times now for test fits, checking clearances etc. it is getting hard to count.

Another test fit after finishing up doors, mirrors etc to test for AC evaporator and measure for steering shaft length. Currently out again to add a third dash vent on the driver side. To fill the big spot I thought was going to be used for an electronic transfer case switch

Went with a ZL1 PWM pump module. Plugs right into my harness without modifications and the ECM will manage it as GM intended. Plus, should have spares long into the future if needed.

Have a BJs tank so had the pre-cut mounting holes welded up and new mounting locations cut. Probably spent at least two hours risning/repeating and then cleaning with wet back to get rid of all the shavings.

Matt

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

-

akguy09

- Posts: 306

- Joined: Mon Aug 30, 2021 6:11 am

- Location: Ellicott, Colorado

Re: 83 Cherokee resto-mod

Matt, Looking good. I am am going to do the same with the inner fender rubber. Just Rivets to hold it on.

1979 Jeep J-10 304/T-18

2017 Jeep JK 2DR

2021 PowerWagon

2017 Jeep JK 2DR

2021 PowerWagon

-

Laredo Matt

Topic author - Posts: 336

- Joined: Fri Jan 08, 2021 3:32 pm

- Location: Washington

Re: 83 Cherokee resto-mod

FYI....I used 1/8" rivet with 3/8" shank I think. Might have been slightly longer, none left so not sure. I added a washer to the back side to make sure I got a good even bite since the rubber is soft. The first few rivets i did without washers and am pretty sure they would have let go. The washer gave it a nice firm metal to metal grip and pinched the rubber over a larger area.

Matt

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

-

wimsurf

- Posts: 191

- Joined: Sat Sep 17, 2016 1:22 pm

- Location: Holland

- Contact:

Re: 83 Cherokee resto-mod

awesome!

Fully appreciate the comment about the dash, mine has been in and out 4 times now, it's a chore but can only be done right once. so worth the effort.

Looking good Matt!

Fully appreciate the comment about the dash, mine has been in and out 4 times now, it's a chore but can only be done right once. so worth the effort.

Looking good Matt!

1984 grand wagoneer

https://www.fsjnetwork.com/forum/viewto ... 35#p197535

- topaz gold | deep night blue,

- AMC 360 v8 | 2019 5.7 hemi,

- TF727 auto 3 speed | 8hp70 8 speed

- nutmeg interior | sand or almond interior to be decided

https://www.fsjnetwork.com/forum/viewto ... 35#p197535

-

CU4WHLN

- Posts: 77

- Joined: Sun Dec 14, 2014 7:18 am

- Location: Michigan

Re: 83 Cherokee resto-mod

Very nice build ...

Just read your full thread. I can appreciate the do it 2 to 6 times scenarios. Been there, done that!

Looks to be coming together well!

The final assembly always takes so much time and effort. Way more than we plan.

All said and done, you will have a killer, unique Jeep.

Keep on it, will be watching.

Jim

Just read your full thread. I can appreciate the do it 2 to 6 times scenarios. Been there, done that!

Looks to be coming together well!

The final assembly always takes so much time and effort. Way more than we plan.

All said and done, you will have a killer, unique Jeep.

Keep on it, will be watching.

Jim

It's not YOURS until you BLEED on it !

+ 01 XJ Cream Puff +16 JK Daily Driver + 85 CJ locked and loaded

+ 03 Rubi + 77 Chief 401 + 79 Chero - Madness: Sold

77 Gen V swap http://www.ifsja.org/forums/vb/showthread.php?t=188457

77 401 build: http://www.ifsja.org/forums/vb/showthre ... ief+begins

79 "Madness" build: http://www.ifsja.org/forums/vb/showthre ... ief+begins

+ 01 XJ Cream Puff +16 JK Daily Driver + 85 CJ locked and loaded

+ 03 Rubi + 77 Chief 401 + 79 Chero - Madness: Sold

77 Gen V swap http://www.ifsja.org/forums/vb/showthread.php?t=188457

77 401 build: http://www.ifsja.org/forums/vb/showthre ... ief+begins

79 "Madness" build: http://www.ifsja.org/forums/vb/showthre ... ief+begins

-

akguy09

- Posts: 306

- Joined: Mon Aug 30, 2021 6:11 am

- Location: Ellicott, Colorado

Re: 83 Cherokee resto-mod

Matt, any new progress?

Marc

Marc

1979 Jeep J-10 304/T-18

2017 Jeep JK 2DR

2021 PowerWagon

2017 Jeep JK 2DR

2021 PowerWagon

-

Laredo Matt

Topic author - Posts: 336

- Joined: Fri Jan 08, 2021 3:32 pm

- Location: Washington

Re: 83 Cherokee resto-mod

some. a lot of the little things that take a bunch of time but no visible progress. Waiting on some key parts so in a bit of a holding pattern

Matt

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

-

akguy09

- Posts: 306

- Joined: Mon Aug 30, 2021 6:11 am

- Location: Ellicott, Colorado

Re: 83 Cherokee resto-mod

Matt when you made your rubber pieces did you trace them first then cut? Or did you cut around the old ones? Did you make them a little bigger? Mine originally did no stick out past the edge of the inner fender

Marc

Marc

1979 Jeep J-10 304/T-18

2017 Jeep JK 2DR

2021 PowerWagon

2017 Jeep JK 2DR

2021 PowerWagon

-

Laredo Matt

Topic author - Posts: 336

- Joined: Fri Jan 08, 2021 3:32 pm

- Location: Washington

Re: 83 Cherokee resto-mod

I traced them out first then cut. I have pictures of mine when I disassembled before removing and they stuck out about 1/2"".

Not able to get pictures now but can you send you the pictures when I was taking it apart to show position.

Not able to get pictures now but can you send you the pictures when I was taking it apart to show position.

Matt

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

-

Laredo Matt

Topic author - Posts: 336

- Joined: Fri Jan 08, 2021 3:32 pm

- Location: Washington

Re: 83 Cherokee resto-mod

It's been a while since I updated the thread. Still moving forward, just slower than expected.

I'm waiting on some A/C parts that have been on back order for several months. Just got FedEx notice they finally shipped and should be here a week from tomorrow. I may have finally sourced a PWM cooling fan. If it works, I should have that in a few weeks.

Tailgate mounted, still needs some adjustments. I'll post separate on that with some pictures and a few questions I'm hoping the forum can help with.

welding up a mount for the remote power steering reservoir. No one has them for the L8T and I need it for hydroboost. I just started playing with cardboard. This is an 18 ga. mock-up. Thin and easy to cut and bend for a rough template to see if it works.

Looks like it will do the job. Set the hood on to check clearances and have 1/2" from cap to closest part of the hood. All good and relatively short and easy run to steering pump. Next, remove pump and get the feed input port machined and tapped for a AN -10 connector.

I transferred the design to 11ga and dropped off to have it plasma cut and the breaks put in. They'll be clean and square and should weld up easy. 5lb hammer and edge of a table aren't going cut it. Hoping they'll get to it before tomorrow so I can weld it up over the weekend.

Floor shifter in. Measuring to make sure I get it centered before I drill mounting holes and cut floor pan for the cable. The picture below is actually after I mounted it and rechecking to make sure it was still centered.

I decided to use nutserts to mount the shifter. Working alone, it was nearly impossible to get the nuts on the bolts, i tried a few times before recalling I had the tool and nutserts I figured as I pull in and out as things progress this will save me a lot of time. I also covered the nutsert body/casing with silicon before crimping down so should be water tight from below. Only thing left, find a grommet for the floor plan.

I figured as I pull in and out as things progress this will save me a lot of time. I also covered the nutsert body/casing with silicon before crimping down so should be water tight from below. Only thing left, find a grommet for the floor plan.

I made a cardboard mock up of the center console. It pretty closely matches the drawing I did and posted way back when. Ugly but served the purpose.

Everything is to scale; cup holders (gotta have em!), power window switch (driver passenger and rear window), seat heater switches, head unit and a/c controls all placed. I made this up before installing the shifter to make sure i had a location that was comfortable everything in easy reach and full shift range. The interior guy will fabricate if I ever get it to him!

Test fitting core support, battery, radiator, steering reservoir etc. Needed something to do to convince myself I was making progress. I laid hood on just to make sure no clearance issues or mods need. All good and almost 1" to spare between electric fan and the accessory drive based on fan specs. I don't see any issues with space in the engine bay. That was a relief, I was worried about the power steering reservoir height most of all.

I'll start pulling the front end back apart now so I have easy access to the engine bay for all plumbing needs; A/C, PS lines, front brake lines etc.

I've been trying to find some rubber bumpers for the tailgate online with no luck. Digging through a box full of "misc old parts" i pulled off. at the bottom, I came across the set I pulled out a year and a half ago. With some soaking and cleaning I can re-use them. They're still in decent shape, at least until I can find better, and fairly supple. Small victory but felt really good.

I managed to cross some tedious but necessary tasks related to assembly off the list as well but nothing picture worthy.

Once the A/C parts and electric fan are here and plumbing is done I will no longer have an excuse to procrastinate on wiring. Never done it and was hoping I could find someone local to help but have not had any success. Just gonna have to buy some new tools and learn.

I'm waiting on some A/C parts that have been on back order for several months. Just got FedEx notice they finally shipped and should be here a week from tomorrow. I may have finally sourced a PWM cooling fan. If it works, I should have that in a few weeks.

Tailgate mounted, still needs some adjustments. I'll post separate on that with some pictures and a few questions I'm hoping the forum can help with.

welding up a mount for the remote power steering reservoir. No one has them for the L8T and I need it for hydroboost. I just started playing with cardboard. This is an 18 ga. mock-up. Thin and easy to cut and bend for a rough template to see if it works.

Looks like it will do the job. Set the hood on to check clearances and have 1/2" from cap to closest part of the hood. All good and relatively short and easy run to steering pump. Next, remove pump and get the feed input port machined and tapped for a AN -10 connector.

I transferred the design to 11ga and dropped off to have it plasma cut and the breaks put in. They'll be clean and square and should weld up easy. 5lb hammer and edge of a table aren't going cut it. Hoping they'll get to it before tomorrow so I can weld it up over the weekend.

Floor shifter in. Measuring to make sure I get it centered before I drill mounting holes and cut floor pan for the cable. The picture below is actually after I mounted it and rechecking to make sure it was still centered.

I decided to use nutserts to mount the shifter. Working alone, it was nearly impossible to get the nuts on the bolts, i tried a few times before recalling I had the tool and nutserts

I made a cardboard mock up of the center console. It pretty closely matches the drawing I did and posted way back when. Ugly but served the purpose.

Everything is to scale; cup holders (gotta have em!), power window switch (driver passenger and rear window), seat heater switches, head unit and a/c controls all placed. I made this up before installing the shifter to make sure i had a location that was comfortable everything in easy reach and full shift range. The interior guy will fabricate if I ever get it to him!

Test fitting core support, battery, radiator, steering reservoir etc. Needed something to do to convince myself I was making progress. I laid hood on just to make sure no clearance issues or mods need. All good and almost 1" to spare between electric fan and the accessory drive based on fan specs. I don't see any issues with space in the engine bay. That was a relief, I was worried about the power steering reservoir height most of all.

I'll start pulling the front end back apart now so I have easy access to the engine bay for all plumbing needs; A/C, PS lines, front brake lines etc.

I've been trying to find some rubber bumpers for the tailgate online with no luck. Digging through a box full of "misc old parts" i pulled off. at the bottom, I came across the set I pulled out a year and a half ago. With some soaking and cleaning I can re-use them. They're still in decent shape, at least until I can find better, and fairly supple. Small victory but felt really good.

I managed to cross some tedious but necessary tasks related to assembly off the list as well but nothing picture worthy.

Once the A/C parts and electric fan are here and plumbing is done I will no longer have an excuse to procrastinate on wiring. Never done it and was hoping I could find someone local to help but have not had any success. Just gonna have to buy some new tools and learn.

Matt

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

-

akguy09

- Posts: 306

- Joined: Mon Aug 30, 2021 6:11 am

- Location: Ellicott, Colorado

Re: 83 Cherokee resto-mod

Matt,

Looking really good. If the grommet you need is for the shifter cable, the check in the specialty drawers in the Hardware aisle at Lowes, they usually have a good selection of sizes

Looking really good. If the grommet you need is for the shifter cable, the check in the specialty drawers in the Hardware aisle at Lowes, they usually have a good selection of sizes

1979 Jeep J-10 304/T-18

2017 Jeep JK 2DR

2021 PowerWagon

2017 Jeep JK 2DR

2021 PowerWagon

-

refinemrh

- Posts: 104

- Joined: Thu Jan 23, 2020 7:15 pm

Re: 83 Cherokee resto-mod

Matt, your jeep is looking awesome. What did you use to paint your side view mirrors and front grill?

-

Pablo

- Posts: 208

- Joined: Sun Dec 15, 2013 6:58 pm

- Location: Arizona

Re: 83 Cherokee resto-mod

Wiring is more tedious than hard. If you are totally new to it, I recommend the book How to Diagnose and Repair Automotive Electrical Systems by Tracy Martin. Pretty much explains all the basics that you would need to know and does it quickly.

- 64 FSJ Wagoneer, under the knife

- 67 FSJ Wagoneer, peacefully taking a break

- 94 XJ, long-armed on 33's. Bolt on ghetto fab fantastic

- 16 BU, wife's snow commuter

-

Laredo Matt

Topic author - Posts: 336

- Joined: Fri Jan 08, 2021 3:32 pm

- Location: Washington

Re: 83 Cherokee resto-mod

Thank you.

The grill surround and mirror bodies are powder coated.

The grille insert is plastic. I used an exact match paint from the same company for grill and all the plastic side markers, headlight, taillight housings bodies and bezels.

It matches color and texture of the powder coat so little surface imperfections aren't visible at all. And I can touch up powder coated parts if they get scratched which is a plus.

Before I painted, I used bulldog adhesion promoter.

Matt

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

-

Laredo Matt

Topic author - Posts: 336

- Joined: Fri Jan 08, 2021 3:32 pm

- Location: Washington

Re: 83 Cherokee resto-mod

Never thought to look at Lowe's. I'll check that next time I'm there.

Matt

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

83 Cherokee Laredo WT

L8T 6.6L, 6L90

GEN III LS Swap (LM7 block)

4L60E

-

akguy09

- Posts: 306

- Joined: Mon Aug 30, 2021 6:11 am

- Location: Ellicott, Colorado

Re: 83 Cherokee resto-mod

Any updates on the Cherokee?

I am deciding on suspension for mine now

I am deciding on suspension for mine now

1979 Jeep J-10 304/T-18

2017 Jeep JK 2DR

2021 PowerWagon

2017 Jeep JK 2DR

2021 PowerWagon